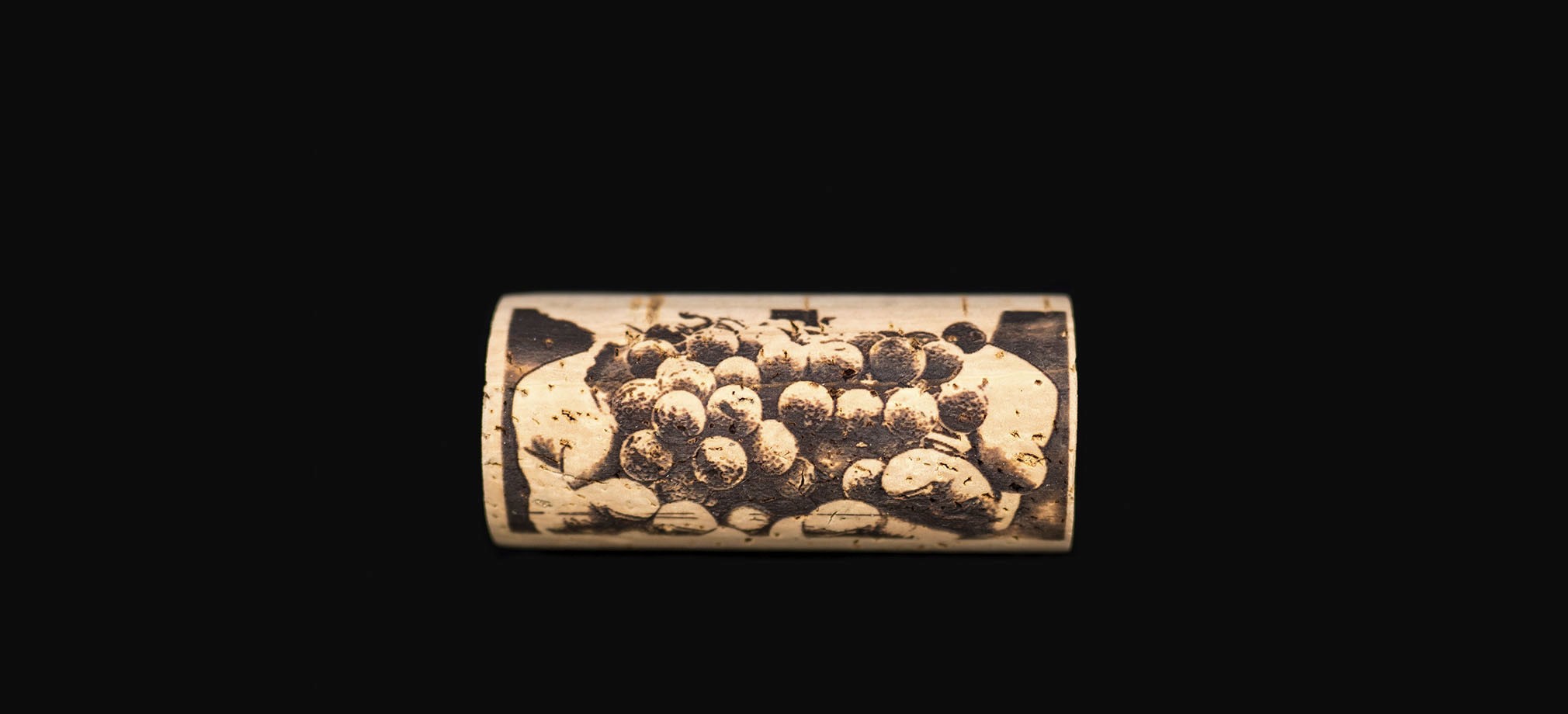

Laser technology provides greater flexibility and a higher quality of engraving than traditional systems, in addition to reduced maintenance costs. It is a clean and sustainable technology which provides high-definition engraving with a range of intensities and dynamics, and it helps to ensure product traceability given that each cork can be designed with a different serial number in one single process. This technique also facilitates small-scale production or the production of limited series without incurring extra costs.

Décork technology can be used to mark the body and ends of a cork and up to 95% of the surface area, providing an extremely high level of finesse in both the chosen font and in the imagery. Depending on which one of the different machine models is used, it is possible to reach a speed of between 3,000 and 24,000 corks per hour thanks to a range of 1 to 4 heads.

Once the design of the engraving has been chosen using simple software and a 15” touch screen, the next stage is the simple and agile set-up process, which is then followed by the production stage. Décork technology automatically turns the corks in the direction that has been chosen while creating the impression.

to mark

the Décork application

customer for acceptance

the cork

Address:

Castellbell 5

08243 Manresa – Barcelona

(SPAIN)

Phone number:

+34 938 77 65 96

For the rest of the needs:

info@decork.net